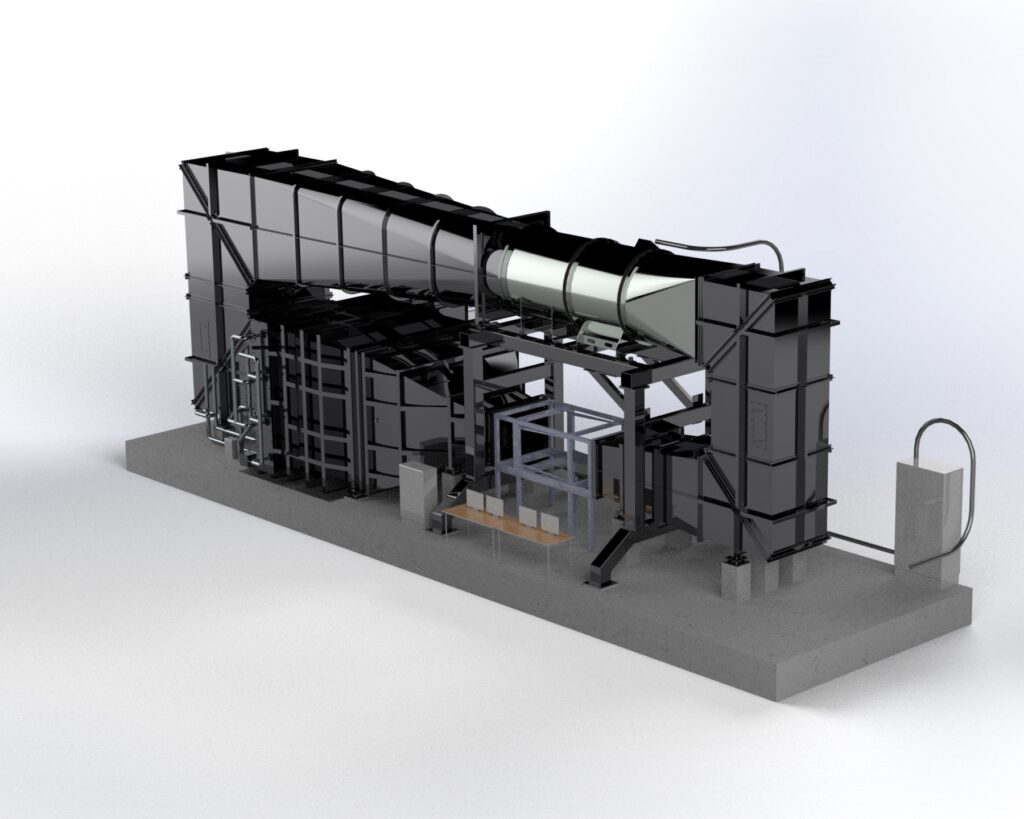

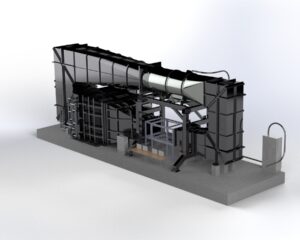

ATE wind tunnels offer a high-performance wind tunnel testing facility capability with various options for future upgrades in capability and performance.

Configurations offered:

For Acoustic and aerodynamic testing

What follows is a small selection of ATE’s expertise in designing and implementing innovative solutions for “real life” situations, resulting from close collaboration with the end user, from initial design concept through to a finished product.

Low-speed wind tunnel at the International Tennis Federation for tennis ball research.

This video by Super Radiator Coils demonstrates one of Ate AEROTECH’s wind tunnels in action.

This wind tunnel was designed to test a large variety of heat exchangers. The test section is interchangeable to allow for numerous configurations of matrix’s for testing.

This Wind Tunnel was designed and built, as a Bench Test Cell, for calibrating and testing of real-life Air Data Probes including Pitot & Pitot-Static Probes, Total Air Temperature Sensors (TATs), and Engine Inlet Temperature Sensors (P2/T2 Sensors). High contraction ratio for high quality, high speed airflow through the test cell. Used for Quality Assurance testing of newly manufactured sensors and periodic maintenance of existing (in service) sensors.

The test cell velocity is nominally Mach = 0.45 (500 f/s), and will allow for the

testing of probes with de-icing circuits energized. Probe lengths of up to 300mm

(12 inches) can be accommodated, with manual adjustment of pitch and yaw angles, providing an accurate simulation of “real flight” flow conditions for a variety of probe designs and mounting attitudes.

In addition to providing the complete wind tunnel, ATE can offer test sections pre-configured with test equipment.

All wind tunnels provided are engineered at our facility in the UK. Each one is bespoke designed to meet with a user's individual requirements. We welcome the opportunity to work with our clients to develop and define their exact needs. Please feel free to contact us: